It is sometimes referred to as glass ceramics because its composition consists of glass and aluminum.

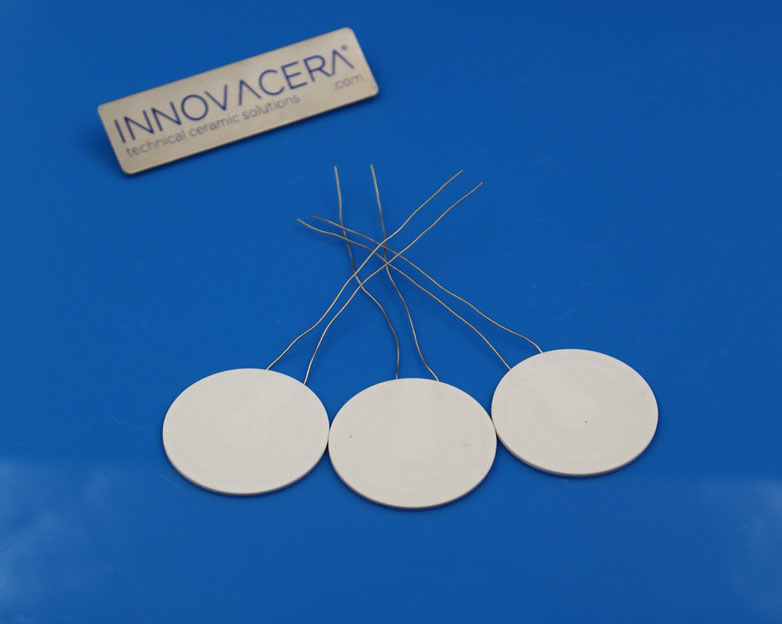

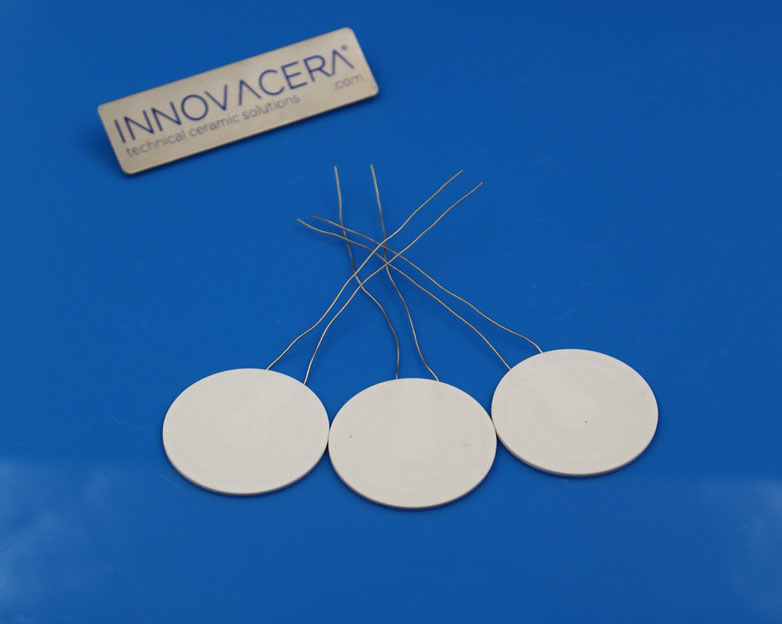

Ltcc alumina ceramic.

Ltcc low temperature co fire ceramics is a multi layer glass ceramic substrate which is co fired with low resistance metal conductors at low firing temperature less than 1000.

The dupont greentape 951 low temperature co fired ceramic ltcc material system combines the benefits of multilayer co fired ceramic and thick film technologies to meet the increasing demand for reliable electronics functioning in extreme heat and other harsh environments.

Its low sintering temperature approximately 900 c allows co firing with highly conductive metals such as silver and gold.

Ltcc low temperature co fired ceramic is a multilayer capable substrate technology offering excellent rf and microwave performance characteristics.

High reliability ceramic substrates ltcc htcc.

Low temperature co fired ceramic ltcc materials systems offer the highest performance packaging solutions for high.

Alumina content 92.

This technology combines many thin layers of ceramic and conductors resulting in a versatile mix of microstrip stripline and three dimensional interconnects making possible a whole mess of designs that are not practical on regular alumina or most soft substrates.

Htcc components generally consist of multilayers of alumina or zirconia with platinum tungsten and molymanganese metalization.

A low cost multilayer low temperature co fired ceramic ltcc package based on a mass production design rule for an mmic up to w band has been developed.

2 3 low cost multilayer ceramic package for flip chip mmic up to w band.

Ltcc also features the ability to embed passive elements such as resistors capacitors and inductors into the ceramic package minimising the size of the completed module.

Material name alumina ltcc.

Apitech s ltcc is an alternative glass ceramic multilayer substrate medium that incorporates conventional thick film material metal systems providing a rugged cost competitive substrate that can incorporate embedded passive components along with more advanced devices such as flipchips and wire bonded bare die.

These fabrication technologies provide unique solutions for high interconnect density compact networks and high.

Ltcc lab offers prototyping and manufacturing services of low temperature co fired ceramic systems multi layer substrate ltcc pcb packaging technology for a wide range of applications.

Ltcc has been used heavily since the 1990s.